Author: Joshua Fagan

Overview

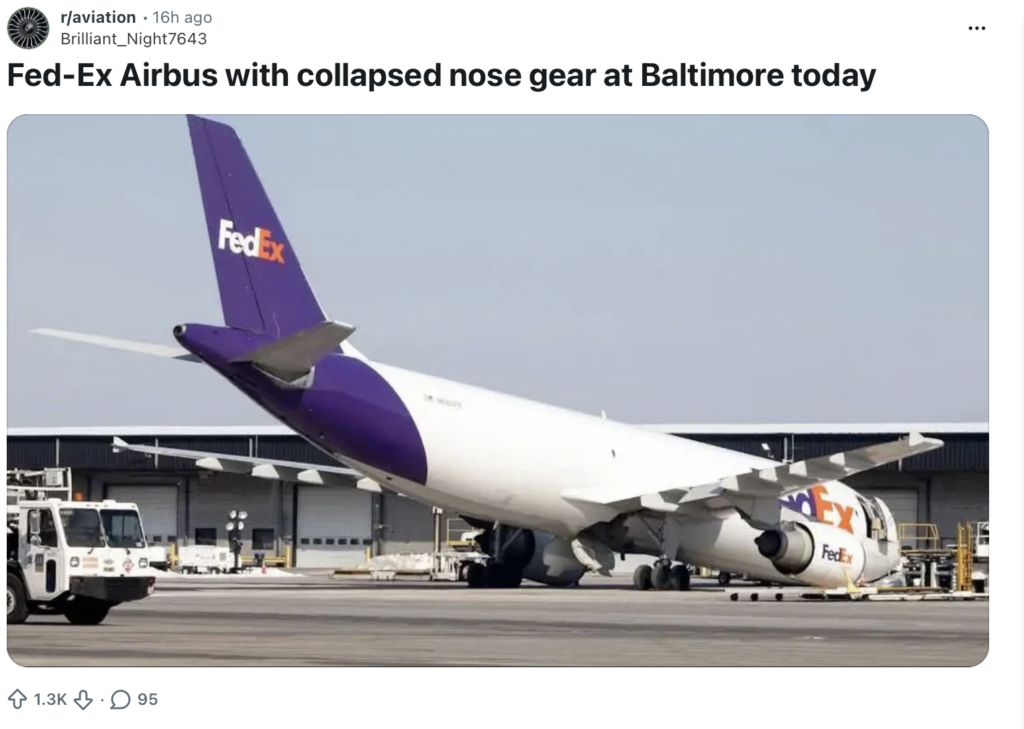

On 5 February 2026, a FedEx Express maintenance incident at Baltimore-Washington International Airport (BWI)drew attention to the challenges of operating ageing freighter fleets. A parked Airbus A300-600F was undergoing maintenance when its nose landing-gear collapsed, causing the forward fuselage to settle onto the tarmac. The aircraft was stationary at the time of the incident. No injuries were reported, and FedEx operations at BWI were not disrupted. The U.S. Federal Aviation Administration (FAA) has been notified, and the cause of the collapse has not yet been publicly identified.

What happened at BWI

The A300 freighter was parked on the cargo ramp near maintenance facilities when the nose landing gear failed, prompting a response from airport emergency services as a precaution. The aircraft was secured and the surrounding area cordoned off. FedEx later confirmed the incident, thanking its employees and local emergency responders and stating that safety remained its top priority. Passenger operations at BWI continued normally while the affected cargo area was temporarily restricted.

Understanding the A300-600F

The Airbus A300-600F is a wide-body freighter design introduced in the late 1980s and was among the first twin-engine wide-body aircraft to enter large-scale cargo service. FedEx has operated one of the world’s largest A300 fleets, primarily on short- and medium-haul routes. While the type has a long record of operational reliability, many airframes remain in service well into their third decade, requiring increasingly intensive inspection and maintenance regimes as they age.

Why nose-gear failures occur

Although the nose landing gear carries less weight than the main gear, it experiences repeated stress during taxi, take-off, and landing cycles. Over time, corrosion, wear, seal degradation, or structural fatigue can weaken components within the assembly. Hydraulic issues affecting the oleo strut can also reduce shock-absorbing capability. During maintenance, aircraft may rely on ground support equipment to redistribute loads, meaning improper support or uneven loading can increase stress on landing-gear components. Investigators will examine the gear assembly, attachment points, and surrounding structure as part of the review.

FedEx’s response and fleet strategy

FedEx confirmed the incident involved a parked aircraft undergoing maintenance and said no injuries occurred. The company indicated that its wider cargo network was unaffected. In recent years, FedEx has been modernising its medium-wide-body fleet, gradually transitioning away from older Airbus freighters toward Boeing 767-300Fs, which offer improved fuel efficiency and simplified maintenance through greater cockpit and systems commonality. However, the A300 fleet continues to play an active role in FedEx’s domestic and regional operations.

Broader context

Nose-gear collapses involving parked aircraft are rare but not unprecedented across the aviation industry. Because such events typically occur at low energy and on the ground, injuries are uncommon. These incidents nonetheless highlight the importance of strict adherence to maintenance procedures and continued monitoring of ageing aircraft structures and systems. Regulators may issue inspection guidance or service bulletins if patterns emerge following investigation findings.

The takeaway

The FedEx nose-gear collapse at BWI underscores the operational realities of maintaining legacy cargo aircraft while ensuring safety margins remain intact. While the Airbus A300-600F has served FedEx reliably for decades, events like this reinforce the need for vigilant maintenance and ongoing fleet renewal. Investigators will determine the specific factors behind the collapse once inspections are complete, and any lessons learned are expected to inform future maintenance practices.