By Vincent Carucci, EAA 1172931

This piece originally ran in the December 2024 issue of EAA Sport Aviation magazine.

I recently completed my Legal Eagle ultralight and named it the Flyin’ Yankee. It was designed by Leonard Milholland, EAA 72307 and the 2015 inductee into the EAA Ultralights Hall of Fame. I got my drawing package and videos from Leonard back in 2016 and set about creating a build plan and finding parts. Eight short years later it’s done! The eight-year period between start and finish doesn’t accurately represent how long it takes to build one of these. This project had to compete with many other things for time and attention. But now with the first one completed, I believe a second one could be built in less than a year. If I were to do it again, I would order the prop at the start of the project as it had a surprisingly long lead time.

So why did I choose the Legal Eagle? Having decided on Part 103 flying, I did an internet search to see what options were available. For me, the Legal Eagle was the best choice for a number of reasons. I like how it resembles a high-wing Cub-style airplane with full three-axis control. I like that the engine of choice was a four-stroke 1/2 VW. Parts are easy to get, and they are reliable as heck. Plus, it just sounds great. I like that it was plansbuilt rather than a purchased a kit. A quality airplane starts with using quality materials. All the materials needed to build were gotten at a number of locations, but my primary supplier was Aircraft Spruce & Specialty.

A lot of different skill sets were learned and used for this project: welding, brazing, gluing, riveting, coping, bending, machining, covering, swaging, wiring, laminating, and vacuum forming to name a few. The plans are pretty thorough, but there is still a lot of room for personalization, so a little design work might be necessary, too. While I looked forward to learning new skills on this project, I wasn’t willing to experiment with the engine. I wanted a proven and reliable engine so I chose a 45-hp 1/2 VW from Scott Casler, EAA 450931, at Hummel Engines. It did not disappoint. So far, it’s been a workhorse. Oil pressure and temperature as well as CHT and rpm have been right on the numbers. Attached to that engine, I have a wooden prop from Performance Propeller that is a work of art.

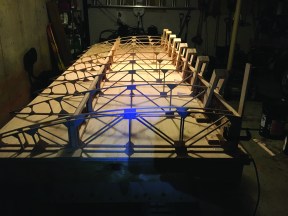

The frame of this aircraft is 4130 steel tubing gas welded together. The tail section is bent aluminum tubing assembled with riveted gussets. The wings are entirely made from Sitka spruce and covered with 1.8-ounce fabric. The paint is premium exterior latex with UV protection. The tail spring is a wood and fiberglass laminate, and the tail wheel uses a scooter wheel in an aluminum mount. The seat cushions are leather-bound foam and weigh only 22 ounces.

For those wondering if this airplane can be built to weigh less than 254 pounds, the answer is YES! One of the mantras frequently repeated by builders is “build to plans.” If you do that, it’ll stay Part 103 compliant. It’s easy for this thing to creep up in weight so an effort needs to be made with every part not to get heavy. Never stop looking for someplace to “add more lightness.” This approach allowed me to add some features that were not in the plans and still not exceed 254 pounds’ dry weight.

The paint scheme and the Normandy invasion stripes are reminiscent of a WWII liaison aircraft or L-bird. The name Flyin’ Yankee and the tail flash on my Legal Eagle are derived from the Connecticut Air National Guard, from which I recently retired after 25 years of service.

Not all airports in Connecticut allow ultralight operations. Fortunately for me, the good people at Simsbury Airport (4B9) welcomed me enthusiastically. Simsbury is a nontowered airport with a 2,200-plus foot paved runway (3/21) and an adjacent 900-foot grass strip. Our airport is notched out of Bradley airport’s (KBDL) Class C airspace, so care must be taken to avoid accidental incursion. It’s just part of the experience. It’s a nice airport to visit if you’re buzzing around Southern New England. It’s a little challenging without being difficult.

Simsbury is home to EAA Chapter 324. I first learned about EAA while looking for a place to fly ultralights. I began showing up to the monthly gatherings and shortly after became a member. Chapter 324 is an active and dynamic group of builders, flyers, and aviation enthusiasts who make the trip to AirVenture every year. The members of our chapter have been hugely helpful and supportive during my build and have contributed in numerous ways. Chapter 324 has become my home, and I’ve since become one of the chapter leaders.

My short-term goal is to complete the EAA Flight Test Manual and test cards all while developing some competent and safe flying skills. If all goes well, I intend to haul this airplane out to Oshkosh and fly it around the Fun Fly Zone during AirVenture 2025.![]()

Attention — Aircraft Builders and Restorers

We would love to share your story with your fellow EAA members in the pages of EAA Sport Aviation magazine, even if it’s a project that’s been completed for a while. Readers consistently rate the “What Our Members are Building/Restoring” section of the magazine as one of their favorites, so don’t miss the chance to show off your handiwork and inspire your peers to start or complete projects of their own. Learn more ->